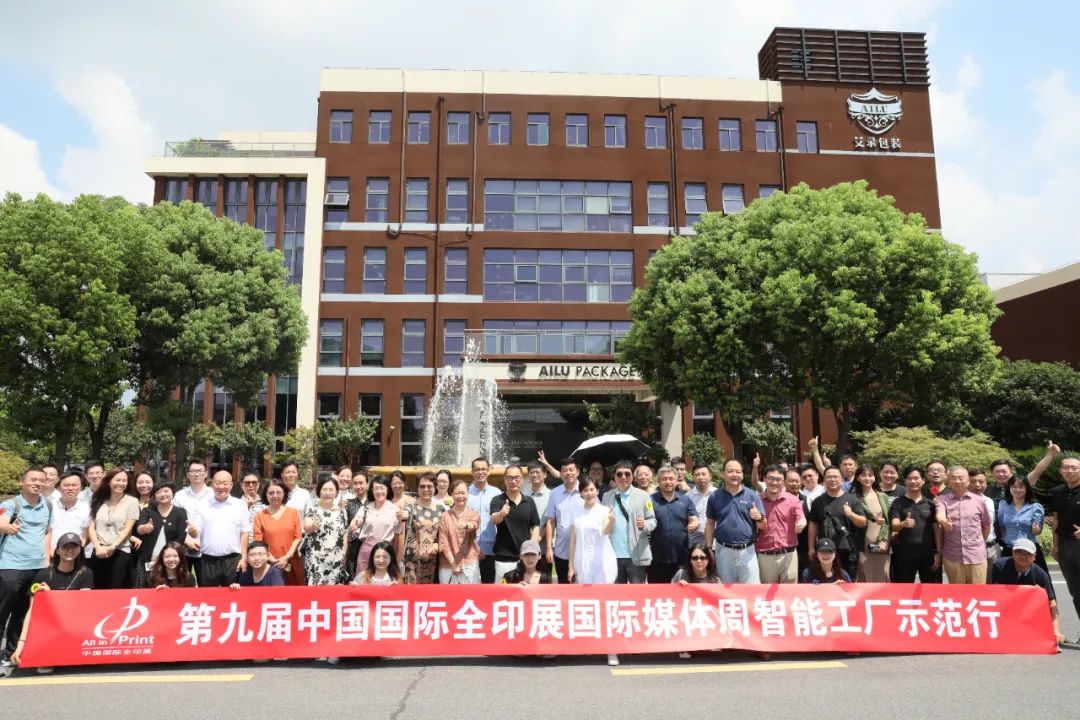

From August 14th to 16th, the “9th China International Printing Exhibition International Media Week” series of events was grandly held in Shanghai. Recently, the Media Week delegation visited Shanghai Ailu Packaging Co., Ltd.

As a benchmark in intelligent printing enterprises in Shanghai, Ailu shared the achievements of smart factory development with the participants and engaged in in-depth discussions on topics such as digitalization and intelligent transformation of printing enterprises.

Shanghai Ailu initiated its digital transformation project in September 2019 and officially completed the comprehensive construction of the fifth phase of the intelligent factory in 2022, a project that lasted 2 years and 4 months.

Centered around data, a sophisticated intelligent warehousing and logistics system was established:

Ailu integrated data sources across systems, analyzed and processed data from enterprise MES, ERP, CRM, WMS, and other systems, and visualized them in the Factory Visualization and Situation Center. The Factory Visualization and Situation Center consists of factory statistical reports, factory decision analysis reports, workshop dashboards, and visitor screens, providing real-time and intuitive displays of production, orders, equipment, shipments, inventory, etc., facilitating subsequent production management.

Digital transformation enhances management efficiency:

With increasing investments in digitalization, Ailu has achieved valuable exploration results, steadily improving its management level and efficiency.

Process reengineering:

Taking the construction of information systems as an opportunity, all major business processes of the enterprise were reorganized, continuously promoting the standardization, normalization, and proceduralization of internal operations.

Reducing communication costs:

With the enhancement of management systems, all data exchanges are achieved accurately and in real-time online, significantly reducing communication costs among various departments of the enterprise.

Full digitization of frontline operations:

Establishing standardized on-site operation processes with intelligent error prevention mechanisms. For example, for machine calling, MES system issues material calling instructions based on BOM, and AGV carts automatically deliver the required materials to the machine line-side warehouse, avoiding manual errors.

Refinement in management:

After the implementation of systems such as PDA barcode, Ailu adheres to the principle of “one item, one code, one label,” managing the majority of materials with serial numbers, achieving quality traceability throughout the entire production process.

Realizing a transparent factory:

Utilizing data transparency, real-time updates, and visualization, Ailu adopts a “let the data speak” approach to enterprise management, driving decisions with data.

In the future, Shanghai Ailu will innovate to sustainably develop the packaging industry, collaborating across sectors to integrate technology and leverage data for leadership.